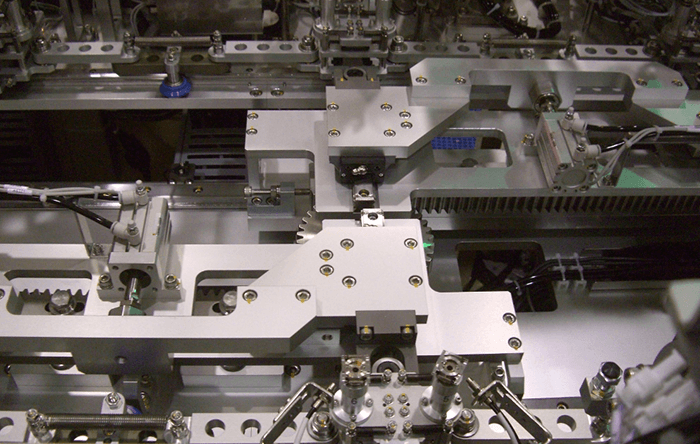

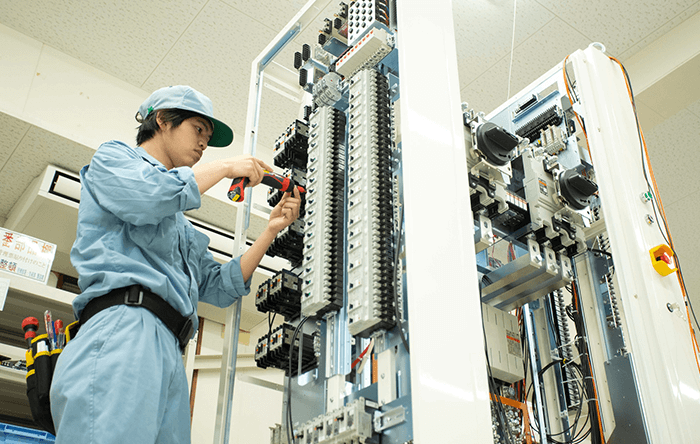

AKシステムの事業内容

お知らせ

-

2025.10.23

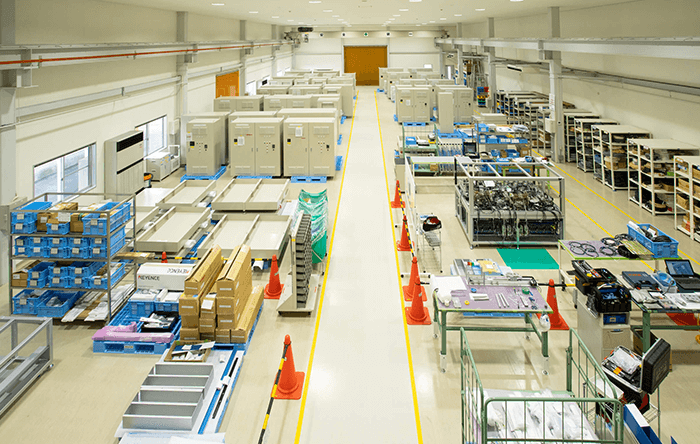

新本社工場 稼働開始のお知らせ

平素より格別のご高配を賜り、誠にありがとうございます。

このたび、当社は業務拡大および生産体制の強化を目的として、

新本社工場を新設し、2025年11月4日より稼働を開始いたします。新しい拠点では、これまで以上にお客様のご要望にお応えできるよう、

より高品質な製品づくりとサービス向上に努めてまいります。

今後とも変わらぬご愛顧のほど、よろしくお願い申し上げます。【新本社工場 所在地・連絡先】

〒870-1201 大分県大分市大字廻栖野2501番10

TEL:097-529-8812 / FAX:097-529-8813

【新組織編成】

・新本社工場

経営管理部、品質保証部、営業統括部、生産統括部、装置製造部

・由布工場

電装製造部、板金製造部(一部:経営管理部、生産統括部) -

2024.12.24

年末年始休業期間のお知らせ

平素は格別のご高配を賜り、厚く御礼申し上げます。

さて、誠に勝手ながら、弊社では下記期間を年末年始休業期間とさせて頂きます。

期間中、皆様にはご不便をおかけしますが、何卒ご理解とご協力のほど、よろしくお願い申しあげます。【営業時間短縮日時】

休業期間:2024年12月28日(土)~2025年1月5日(日)

業務開始:2025年1月6日(月) -

2024.11.29

社内行事に伴う営業時間短縮のお知らせ

平素は格別のお引き立てに預かり、厚く御礼申し上げます。

さて、弊社では社内行事開催のため、下記の通り営業時間の短縮をさせて頂きます。

皆様にはご不便をおかけしますが、何卒ご理解とご協力のほど、よろしくお願い申しあげます。【営業時間短縮日時】

対象日:2024年11月29日(金)

営業時間:8時30分~16時00分 迄16時以降に頂いた問合せやFAXについては、12月2日(月)より順次対応をさせて頂きます。

ご了承お願いいたします。 -

2024.11.27

新本社工場_起工式

平素は格別のご高配を賜り、厚く御礼申し上げます。

2024/11/22 新本社工場建設予定地において起工式が執り行われました。

当日は天候にも恵まれ、素晴らしい船出をきることができました。

式の終わりには、代表取締役社長 古手川瑛保より、出席者への感謝の意と今後のAKシステムの発展に向けた強い決意が述べられました。

新本社工場建設に伴い、近隣住民の皆さま・関係企業の皆さまにはご迷惑をおかけいたしますが、何とぞご高承の上、今後とも変わらぬご支援を賜りますようお願い申し上げます。

-

2024.10.29

地域牽引企業創出事業支援対象企業に認定されました。

平素は格別のご高配を賜り、厚く御礼申し上げます。

2024/10/25 佐藤 樹一郎県知事より、大分県地域牽引企業創出事業の認定証が交付されました。

当事業の目的は、『持続的な成長を通じて地域の雇用や産業活力を生み出し県経済をリードする地場中小企業の創出を図るため、優れた経営基盤を活かした経営戦略により業容拡大を目指す企業に対して総合的な支援を行う。』というもので、対象者要件を満たす優れた中小企業として、この度認定をいただきました。

今後も大分県により一層貢献し、地域を牽引できる企業となるために尽力して参ります。

今後ともご愛顧の程、よろしくお願い申し上げます。

ギャラリー